How to Partner with Chinese Injection Molding Companies

The important meeting has recently finished, your new product has been approved, the timeline is aggressive, and funding is, to put it mildly, limited. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

Of course, you acknowledge. It makes sense on paper. Savings can be substantial. However, your brain is racing with concerns. You know the rumors, don’t you? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It feels like walking a thin line between big savings and total project failure.

However, here’s the reality. Procuring plastic mold company needn’t be a roll of the dice. It’s a project, just like any other. And like any project, it succeeds or fails based on the process you follow. It’s less about finding the absolute cheapest quote and more about finding the right partner and managing the process with your eyes wide open. Ignore the nightmare anecdotes. Let’s go through a step-by-step guide to succeed.

Step One: Do Your Homework

Before you mention “supplier” or browse Alibaba, organize your internal data. In fact, most overseas manufacturing headaches stem from a vague or incomplete RFQ. Don’t assume a remote factory can guess your needs. Sending a vague request is like asking a builder to quote you for “a house.” The responses you get will be all over the map, and none of them will be useful.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. This package is your project’s foundation.

What should you include?

First, your 3D CAD files. They’re essential. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This is the master blueprint for your part’s geometry.

Yet 3D models don’t cover everything. Add comprehensive 2D plans. This details critical info missing from the 3D file. Think tolerances, material grades, finish specs, and any feature-critical notes. Any seal surfaces or critical hole sizes must be clearly labeled.

Then specify the material. Don’t just say “Plastic.” Even “ABS” alone is too vague. Be specific. If you need SABIC Cycolac MG38 in black, say exactly that. Why? Because resin grades number in the thousands. Defining the exact material guarantees the performance and appearance you designed with plastic mold injection.

A good supplier can suggest alternatives, but you need to give them a clear starting point.

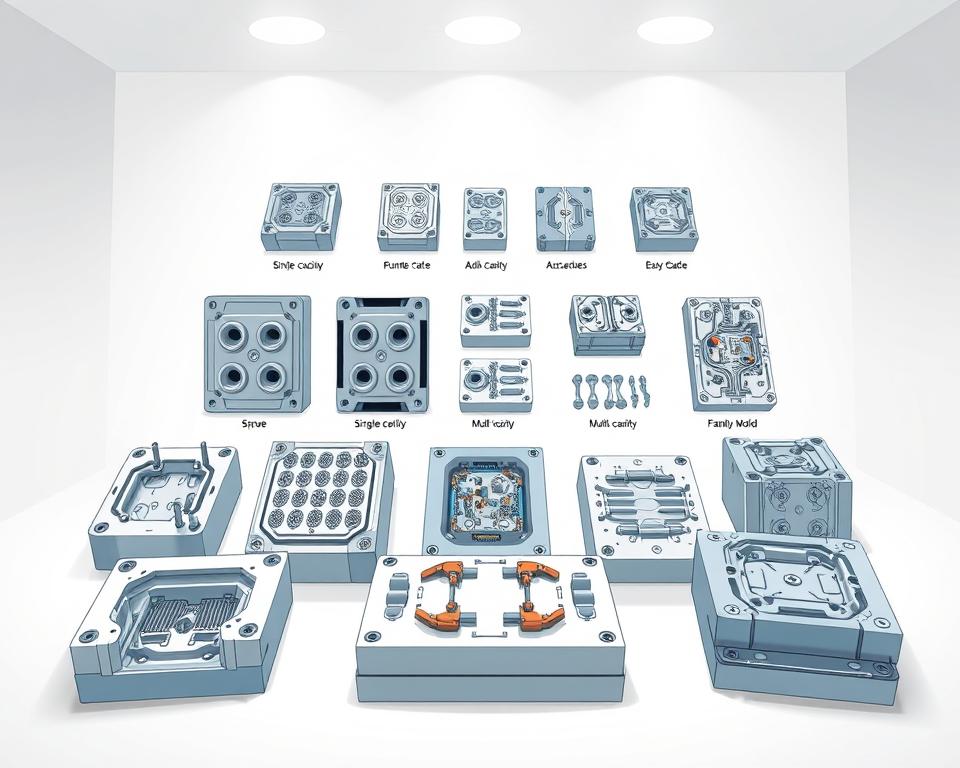

Lastly, add your business data. State your EAU. You must specify if it’s a 1K-part tool or a 1M-part production run. The tool design, the number of cavities, and the price per part all hinge on this number.

Finding the Right Supplier

Okay, your RFQ package is a work of art. now, who do you send it to? The web is vast but overwhelming. Locating vendors is easy; vetting them is the real challenge.

Your search will likely start on platforms like Alibaba or Made-in-China.com. They offer breadth but not depth. Use them to build a shortlist, not the final list. Aim for a preliminary list of 10–15 potential partners.

However, don’t end your search there. Perhaps hire a local sourcing specialist. Yes, they take a cut. Yet top agents deliver reliable, audited suppliers. They bridge language and cultural gaps. On your first run, this is like insurance. Think of it as insurance for your project timeline.

Also consider trade fairs. If you can attend, shows such as Chinaplas transform sourcing. Meeting onsite is unbeatable. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. Also, leverage the tried-and-true referral network. Tap your professional contacts. Peer endorsements carry huge weight.

Separating Real Suppliers from Pretenders

After firing off that RFQ to a broad pool, estimates roll in. Some prices will undercut logic, others will shock you. Your job now is to vet these companies and narrow it down to two or three serious contenders.

How do you do that? It’s a bit of an art and a science.

Step one: audit communication. Are their replies prompt and clear? Can they handle detailed English exchanges? But the key: do they probe your RFQ? A great supplier will review your RFQ and come back with thoughts. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” That’s a huge positive sign. It proves their expertise and involvement. Anyone who simply agrees to all specs is a red flag.

Next, dig into their technical capabilities. Ask for a list of their equipment. More importantly, ask for case studies of parts they’ve made that are similar to yours in size, complexity, or material. Don’t pick a micro-molding shop for large components.

Finally, inspect the factory. This is not optional. Just as you interview hires, audit suppliers. You can either go yourself or, more practically, hire a third-party auditing firm in China to do it for you. They’ll send a local inspector to the factory for a day. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. It’s the best few hundred dollars you will ever spend on your project.

From Digital File to Physical Part

Once you’ve chosen your supplier. you agree on 50% deposit to start toolmaking and 50% balance after sample sign-off. Then comes the real action.

The first thing you should get back after sending your payment is a DFM report. DFM means Design for Manufacturability. It’s the engineering critique for moldability. They’ll flag thick sections prone to sink, sharp edges that stress, or insufficient draft. A thorough DFM is a sign of a professional operation. It’s a collaboration. You iterate with their team to optimize the mold.

Once the DFM is approved, they’ll start cutting steel to make your injection mold tool. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These are your initial mold shots. They are your moment of truth.

T1 parts usually require adjustments. That’s standard process. You’ll find minor defects, off-spec dimensions, or finish issues. You critique, they refine, and T2 plastic mold company parts arrive. This process might take a couple of rounds. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

Eventually, you will receive a part that is perfect. Dimensions, finish, and performance all check out. This is your golden sample. You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Completing the Sourcing Journey

Landing the golden sample is huge, yet the project continues. Now you’re entering the mass production phase. How can you keep part #10,000 matching your golden sample?

You need a clear Quality Control plan. This often involves a pre-shipment inspection. Again, you can hire a third-party service. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. You receive a full report with images and measurements. Once you sign off, you greenlight shipping and the last payment. This step saves you from a container of rejects.

Finally, think about logistics. Clarify your Incoterms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or EXW, shifting all transport to you? Your Incoterm selection drives landed expenses.

China sourcing is a long-haul effort. It relies on partnership-building. Treat them like a partner, not just a line item on a spreadsheet. Open dialogue, trust, and rigorous procedure deliver results. Certainly, it’s complex. However, armed with this guide, you’ll secure savings and keep high standards intact. You’re set to succeed.