Eco-Friendly Precious Metal Recovery Handbook

Did you know that more than $60 billion worth of precious metals are discarded each year in electronic waste alone? That eye-opening statistic shows how important recycling these metals really is. Not only does it boost economic health, it also protects our environment. When we recover gold, silver, platinum, and palladium, we reduce pollution and conserve resources.

Leaders such as Dongsheng Metal Trading are paving the way for sustainable recycling. They make sure those precious metals get reused rather than landfilled. Such a precious metals recycling model drives eco-friendly recycling and sustainable methods.

Major Takeaways

- More than $60 billion of precious metals end up in e-waste each year.

- Recovering these metals cuts eco-impact and preserves resources.

- Gold, silver, platinum, and palladium top the list of valuable metals.

- Green recycling methods are essential for a sustainable future.

- Companies like Dongsheng Metal Trading specialize in metal recycling.

What Makes Precious Metals So Valuable

Precious metals are rare, naturally occurring metallic elements that have captured the interest of investors and industries alike. Gold, silver, platinum, and palladium stand out for their distinct qualities. They offer conductivity, resist corrosion, and occur in limited supply. The extraction and processing of these metals require considerable resources, underscoring the importance of recycling precious metals.

The value of precious metals is influenced by market demand and the inherent qualities of each metal. Recycling precious metals plays a critical role in sustaining the supply chain. It lowers the ecological damage from mining. Advanced recycling can bring metals back to their initial quality. This preserves finite resources while yielding economic benefits.

Precious Metals Explained

Precious metals possess unique characteristics that make them desirable for a variety of applications. Economic value stems from their scarcity and innate qualities. For example:

- Gold: Admired for its luster and low corrosion.

- Silver: Known for flexible uses and excellent conductivity.

- Pt: Celebrated for its durability and catalytic properties.

- Pd: Increasingly popular in automotive and electronic applications.

Why Recycle Precious Metals?

Recovering precious metals plays a crucial role in sustainability. It preserves resources and lessens the environmental cost of mining. Consider these advantages:

- Reduction of environmental degradation caused by mining operations.

- Lower energy consumption compared to extracting new metals from the earth.

- Supporting a circular economy via material reuse.

- Potential for financial gains through the reclaiming of high-value materials.

Why Precious Metal Recycling Matters

Recycling precious metals offers substantial environmental and economic benefits. Pointing out these perks shows how to shrink our eco-impact. It also drives economic growth and stability.

Environmental Benefits

Recycling metals yields major environmental perks. When we recover metals from e-waste and scrap, landfill volume drops. It curbs mining demand and preserves nature.

This approach minimizes the harmful effects of mining, such as habitat destruction and pollution. By prioritizing recycling, we work toward a greener tomorrow.

Economic Benefits

The economic benefits of recycling are equally compelling. Recycling precious metals can lower manufacturing costs. This allows industries to use reclaimed metals instead of new ones.

It produces recycling-sector employment and strengthens markets with growing recycled-metal needs. By leveraging these economic advantages, businesses can improve their profitability. They also contribute to a greener economy.

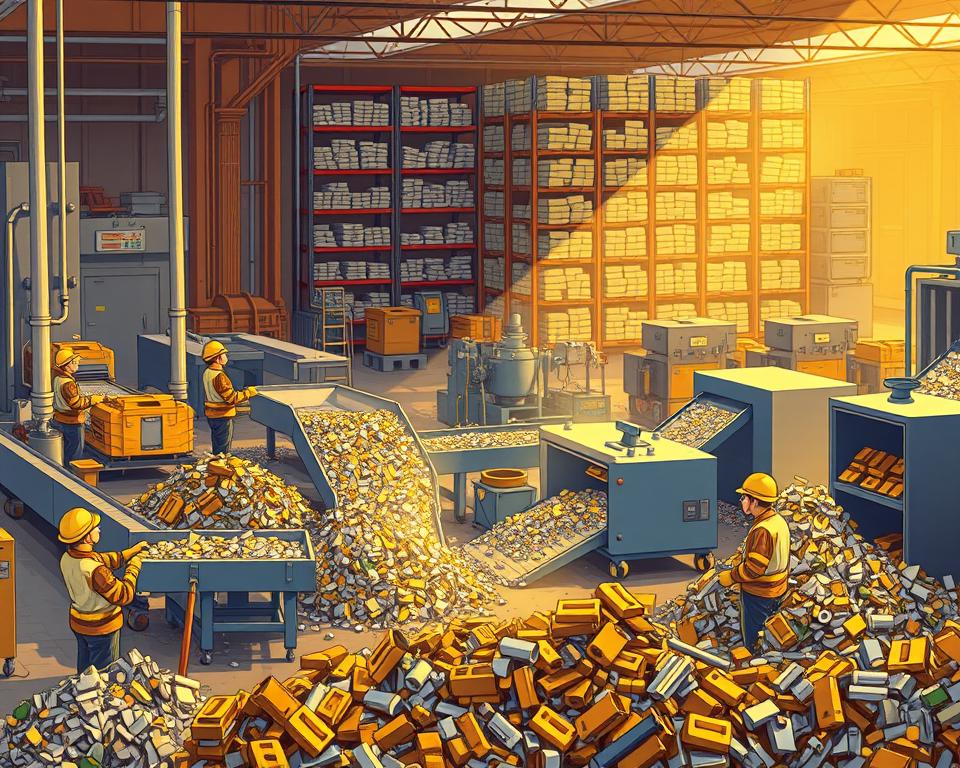

How Precious Metals are Recycled

Recovering precious metals involves multiple steps for peak efficiency. Collection of e-waste, jewelry, and industrial scrap kicks off the process. They are sorted, decontaminated, and analyzed to gauge composition and value.

Recovery Steps

This systematic approach is vital for effective metal recovery. Every phase aims to maximize precious-metal returns. Sorting separates metals by type and purity. Decontamination eliminates residues that block recovery. Testing measures metal content to select proper recycling methods.

Recovery Methods

Cutting-edge processes boost precious-metal recovery. Thermal reduction applies intense heat to isolate metals. Melting refines and aggregates metals, while wet chemical processes are used for delicate separations. Firms such as Dongsheng Metal Trading apply these techniques to raise recovery and profits.

Types of Precious Metals that can be Recycled

Scrap recovery benefits both Earth and economy. Numerous precious metals lend themselves to recycling, serving both business and environment. Awareness of recyclable metals guides consumers and companies.

Gold, Silver, and Platinum

Gold, silver, and platinum stand out among precious metals. They’re found in jewelry, coins, and industrial uses. Gold recovery is widespread because of its worth and need. Silver recovery matters too, thanks to its role in imaging, tech, and solar.

Platinum, though less common, is valuable, mainly in catalytic converters.

E-Waste Metals

E-waste metals present special recovery opportunities. Smartphones, laptops, and tablets contain rare metals like palladium and indium. Recovering such metals diminishes e-waste and yields vital materials.

The need to recycle these metals is critical. Industries aim to minimize waste and efficiently recycle resources.

Industries that Benefit from Precious Metal Recycling

Metal recovery underpins major sectors by supplying reclaimed resources sustainably. Electronics, which embeds metals in gadgets, gains the most. Aerospace and healthcare rely on them for vital parts. Exploring how these industries recycle precious metals reveals the environmental and economic benefits.

E-Waste Sector

Because devices abound with metals, electronics tops recycling efforts. Fast tech progress fuels growing e-waste volumes. Thus, recycling gold, silver, and palladium efficiently becomes vital. It preserves nature and lowers mining-driven CO₂ emissions.

Firms ramp up recycling to hit sustainability targets. That change bolsters resource saving and ecosafety.

Aerospace and Medical Equipment

Metal recovery is key in aerospace and medical sectors where metals are in vital parts. Alloys prized for strength and anti-corrosion make up flight and medical components. Recycling these metals can significantly lower material costs and comply with environmental regulations.

These sectors know green recovery eases resource shortages. And it improves operations, making metal recycling a smart green tactic.

Selecting Recycling Partners

Choosing reputable metal recyclers is vital for success. Be sure to quiz them on their methods. Knowing their pricing and processing methods can greatly affect your experience. By comparing services, you can see what each company offers and make a smart choice.

Questions to Ask Recycling Companies

- What certifications do you hold regarding precious metal recovery?

- How do you process various precious metals?

- What yields can you deliver for gold, silver, and more?

- What is your pricing structure and are there extra charges?

- Do you have client testimonials or references?

Service & Price Comparison

When searching for a recycler, it’s vital to compare different companies based on their services. Create a table to compare key factors such as:

| Company Name | Recovery Rate (%) | Processing Fee ($) | Turnaround Time (Days) |

|---|---|---|---|

| Recycling Co. A | 95 | 50 | 7 |

| Recycling Co. B | 90 | 45 | 5 |

| Recycling Co. C | 92 | 55 | 10 |

Side-by-side comparisons help pinpoint the ideal recycler. That way, you maximize returns and maintain quality.

Recycling Precious Metals: A Green Guide

Knowing recycler operations matters if you recycle metals. These experts manage the entire process, from collection to processing. That approach drives top efficiency and returns.

How Recyclers Operate

They apply high-tech processes—testing, sorting, refining—to recover metals. They start by collecting metal scraps from various sources. Afterwards, they apply refined techniques to isolate each metal. In the last stage, precious metals are refined to purity.

That workflow both boosts recovery and promotes green methods. It’s fundamental to building a sustainable future.

Selecting Your Ideal Recycler

You’ll want to weigh several factors in your choice. First, look at their environmental practices. Now more than ever, green commitment is crucial. Also, examine if they handle everything or only certain stages.

Your budget will influence your choice. Request estimates from multiple firms. Companies like Dongsheng Metal Trading offer customized solutions for various industries. They are a reliable choice for specific recycling needs.

Pick the Right Facility

Recovery facilities are central to green waste solutions. It encompasses various recycling centers, each tailored to specific metal recovery needs. Understanding these facilities improves access to recyclers and their services. It aids companies and conserves nature.

Facility Categories

There’s a broad spectrum of recycling operations. Some focus on precious metals, while others handle a wide range of materials. Here are a few common types:

- Scrap yards process a broad mix of metal types.

- Precious Metal Recovery Companies: With a focus on high-value materials such as gold, silver, and platinum, these companies offer refined processing techniques.

- Electronics recyclers extract metals from old gadgets.

Location and Access to Facilities

Accessibility to recyclers is key for efficient metal recovery. Companies should evaluate haulage considerations. Here are some factors that influence access:

| Factor | Description |

|---|---|

| Proximity | Closer sites cut shipping costs and delays. |

| Networking | Strong ties with local centers streamline recovery. |

| Service Range | Awareness of service menus aids in picking the right center. |

In sum, selecting the right type of recycling center and ensuring convenient access can significantly enhance the efficiency of metal recycling operations.

Recovering Metals from E-Waste

Discarded electronics threaten the environment. Discarded devices often contain precious metals that can be recovered through recycling. That underscores viewing e-waste as a metal source.

Metals in Devices

Many electronic devices hold small amounts of precious metals like gold, silver, and palladium. These metals are found in various parts:

- Circuit boards

- Connectors and ports

- Capacitors and resistors

- Battery terminals

From phones to TVs, electronics pack precious metals. By recycling, we retrieve and reuse these valuable elements.

Why Recycle E-Waste?

E-waste recycling is vital for both environmental protection and resource recovery. It reduces landfill waste and saves natural resources. Key perks include:

- It cuts ecological hazards from poor e-waste handling

- It curbs carbon footprints with sustainable recycling

- It bolsters circular models by returning scrap to production

Promoting e-waste recovery advances resource stewardship. It lays the groundwork for a greener future.

The Future of Precious Metal Recycling

Metal recycling is evolving, spurred by tech advances and green initiatives. With resource conservation rising, recyclers are innovating. By integrating novel processes, they pave the way forward.

Eco-Friendly Recycling Innovations

Today’s sustainable recycling prioritizes waste reduction and low impact. Businesses adopt green packaging and energy-saving techniques. Such moves match worldwide green goals and nudge industries to be more eco-responsible.

New Metal Recovery Tech

New methods in recovery enhance recycling performance. Automated sorters and hydrometallurgy ramp up yield. These innovations not only increase resource extraction but also reduce environmental impact, marking a significant step forward in recycling precious metals.

Launching a Metal Recycling Startup

Building a metal recycling enterprise calls for thorough planning and industry knowledge. Entrepreneurs must outline key steps to build a strong foundation and adhere to industry regulations. That means in-depth market analysis and client identification. Securing licenses and legal compliance is crucial for long-term viability.

Steps to Establishing a Business

Setting up a precious metal recycling venture requires several essential steps:

- Analyze market demand and competitor landscape.

- Create a comprehensive plan with objectives and tactics.

- Invest in equipment tailored to your process needs.

- Obtain capital via loans or investors.

- Get all required permits and licenses.

- Launch marketing to attract clientele.

Compliance and Certifications

Understanding legal aspects when starting a precious metal recycling business is critical. Meeting environmental rules protects your operation and the planet. Must-know compliance points:

- Getting licensed by appropriate agencies.

- Following all levels of waste and recycling regulations.

- Training staff in safety protocols and best practices.

In Closing

Recovering precious metals conserves resources and protects our planet. It helps people and companies cut waste’s ecological toll. The recovered metals reduce mining needs and boost the economy by creating jobs in recycling.

Recycling goes beyond environmental benefits, also providing economic advantages. Working with Dongsheng Metal Trading guarantees green standards. This collaboration strengthens the circular economy, benefiting both recyclers and consumers.

A sustainable tomorrow hinges on our joint metal-recycling efforts. Increased awareness builds a culture of green consumption and care. Implementing these measures supports us today and safeguards future generations.